June 2010 Vol. 237 No. 6

TechNotes

HMI/SCADA Solution Works For ENSTOR

Natural gas is an important energy source for reducing pollution. Compared to coal and oil, combustion of natural gas releases significantly lower amounts of harmful pollutants and carbon dioxide. After its exploration, production and transportation, natural gas can be stored for an indefinite period of time for future use.

Reconditioned depleted reservoirs and salt caverns make ideal vessels for storing natural gas. Depleted reservoirs are formations that have been tapped of all their recoverable natural gas. Salt caverns are made in salt bed deposits left from when sea covered the land. By drilling a well down into the salt bed, and cycling large amounts of water through the well to dissolve the salt, large caverns can be created in the salt.

ENSTOR, a subsidiary of Iberdrola Renewables, is a company dedicated to the storage of liquid natural gas. With facilities including both depleted reservoirs and salt caverns, ENSTOR maintains five repositories throughout North America, and is currently developing two more sites. ICONICS software, implemented by Accelemetrics, Inc., an ICONICS Gold Certified Partner, helps ENSTOR to responsibly and safely receive, store and deliver natural gas, the cleanest burning fossil fuel.

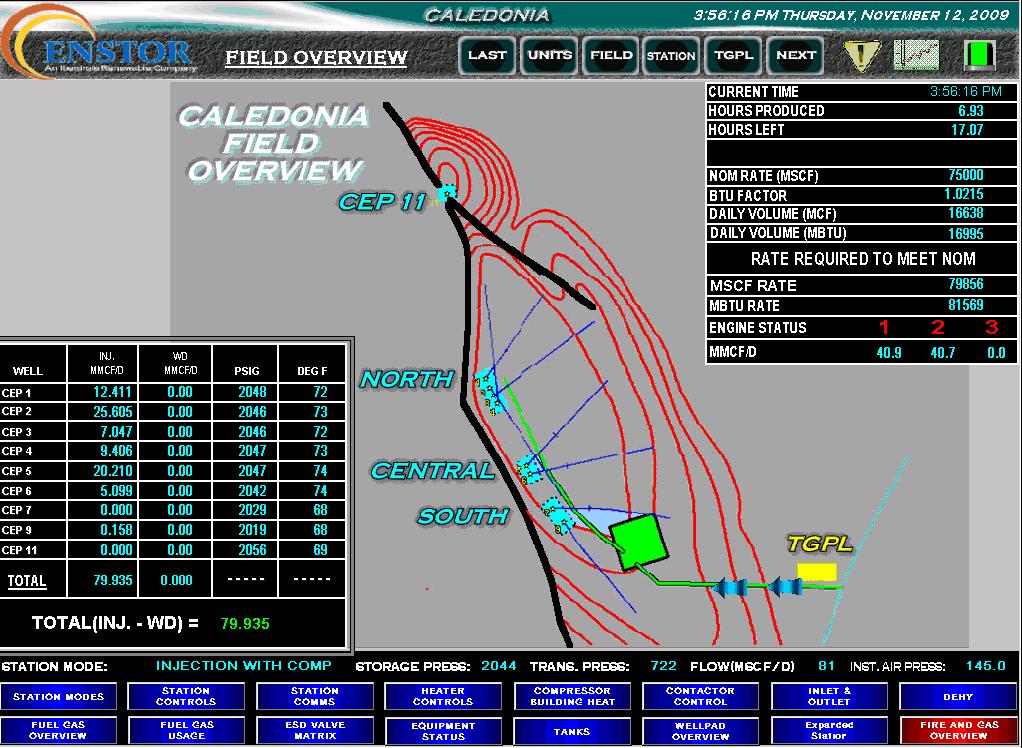

ICONICS Software Deployed GENESIS32™ is used to monitor and control ENSTOR’s storage plant facilities. AlarmWorX™32 and TrendWorX™32 modules help operators maintain efficiency. BizViz™32 and PortalWorX™32 deliver visualization to the corporate level.

ENSTOR leverages its various gas storage and hub-service facilities to provide customers superior transfer access between major pipelines as well as rapid injection and withdrawal storage capacity. In ENSTOR’s facilities, the GENESIS32-based control system uses PLCs and gas flow computers that monitor and control a variety of compressors, gas meters, valves, dehydrators, and safety equipment to manage natural gas injection, withdrawal, receipt and delivery.

The Alberta Hub in Canada, Caledonia in Mississippi, Freebird in Alabama, Grama Ridge in New Mexico, and Katy Hub near Houston comprise ENSTOR’s strategically located gas-storage facilities. In addition, the Katy facility serves as the corporate centralized monitoring and control location.

Each location has a dedicated control room where operators monitor and control both storage plant and pipeline interconnection points (where customers deliver and receive gas). TrendWorX data from five facilities is relayed to the Katy storage facility into an Accelemetrics gas storage data warehouse where data can be reported and interfaced with cleanly by other downstream information systems. PortalWorX delivers a higher level corporate view to headquarters in Houston.

ICONICS’ software solution demonstrated its flexibility and ease of use with installations taking only a few months at each facility.

Accelemetrics was able to build several specialized gas storage specific applications that tied into GENESIS32. Specifically, by leveraging ICONICS DataWorX OPC tunneling and data aggregation capabilities, Accelemetrics built CommFidence, a customized gas-storage proactive alarming system.

The system monitors connectivity between natural gas flow computers and chromatographs to confirm that communication is successful, intelligently checks for specialized gas measurement errors, and monitors overall system functionality. The Accelemetrics Gas Storage Processing Engine performs a variety of facility operational functions including line pack calculations, compressor fuel monitoring, well volume allocations, plant balancing, and regulatory emissions reporting.

With five operating facilities through North America and two facilities under development, ENSTOR realizes operational flexibility demanded by the volatile North American natural gas markets. Plans are in place to upgrade to newest version of ICONICS’ GraphWorX32.

Comments