April 2010 Vol. 237 No. 4

Projects

Weatherford Helps Cut Commissioning Costs In Deepwater Field Off Ghana

Weatherford Pipeline & Specialty Services group was awarded a contract by Technip for pre-commissioning and commissioning services on the Jubilee field development off West Africa.

The contract covers pigging of production, water and gas injection flowlines; hydrostatic testing of the flowlines, riser and jumpers; and dewatering of the gas-injection system. During installation and post installation, Weatherford will perform electrical and pressure monitoring and testing of the umbilicals from the floating, production, storage, and offloading (FPSO) vessel.

Plans call for Weatherford to use its patented Denizen subsea pipeline commissioning system on the project, which will be the first deployment of such technology in Ghana. The company will mobilize a high-pressure membrane-generated nitrogen spread which will be based on a support vessel and used to dewater the gas injection riser and flowlines.

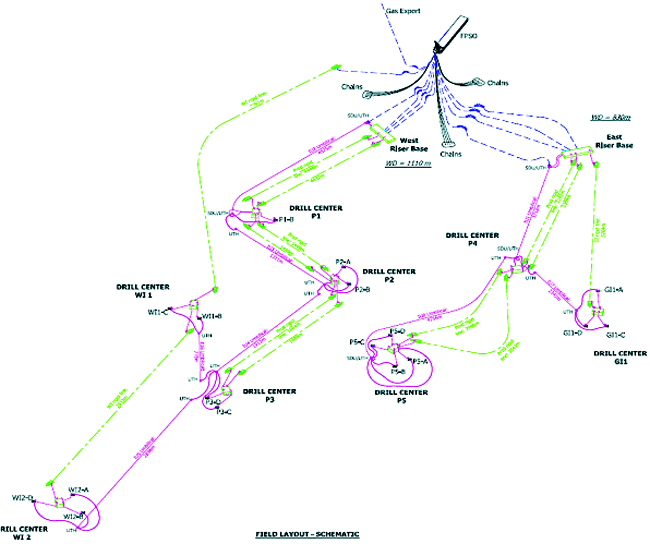

Situated in the Deepwater Tano and West Cape Three Points blocks, the Jubilee field lies 60 km offshore Ghana. The Jubilee field development comprises production wells, water-injection and gas-injection wells to be tied in via manifolds and riser bases to a floating production, storage, and an FPSO located 130 km west of Takoradi. The water depth across the entire Jubilee Field area varies from 900-1,700 meters.

Pre-commissioning Process

The Denizen subsea pipeline pre-commissioning system uses a remotely operated vehicle (ROV) that mechanically displaces or introduces pipeline fluids to perform hydrostatic testing of infield and transportation pipeline systems in up to 10,000 feet of water.

Once it is ready for operation, the surface team submerges the ROV-based Denizen unit and engages it with the flowline. The unit serves as a full-service testing and data-recording tool – introducing fluids and performing hydrostatic testing.

Critical metrics, such as pressure, temperature and flow, are transmitted in real time to a small support vessel through the ROV’s umbilical, recorded on solid-state memory, or visually observed via a light-activated display.

Weatherford says that because of the downsized operating requirement, the Denizen method reduces crew sizes by more than two-thirds; cuts mobilization cost and complexity; improves operational safety; and minimizes temperature-stabilization duration.

The Denizen is also useful in inclement weather. It can be recovered to the surface in an expedient manner while the pressure and temperature in the pipeline is continually monitored for up to 14 days using the remote data-logging unit. When weather conditions improve, operations can quickly resume. Once the ROV is back on station, all recorded operations data can be retrieved and analyzed.

Dewatering Operations

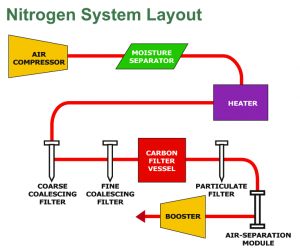

To dewater the gas injection riser and flowlines on the project, Weatherford will rely on its nitrogen production unit (NPU) that can deliver 5,000 psi (345 bar) with flow rates ranging from 300 scfm (8.5 m3/min) to more than 3,000 scfm (85 m3/min). System N2 purities range from 92-99% at dew points of up to -900F, making it suitable for a host of applications, including: (mine fire suppression; purging and displacing unwanted products; drying; pressure testing; helium leak detection; foam inserting; preservation; gas lifting; and enhanced oil recovery.)

To begin the process of N2 production, the NPU receives compressed air – at least 175 psi (12 bar), then separates the oxygen from the compressed air. The air-separation processes are performed using the membrane modules that are contained within the NPU. Each module is constructed of millions of hollow fibers the diameter of a human hair.

Compressed air is forced through the hollow fibers. The holes in the walls are small enough that CO, CO2 and O2 will exit through them under pressure. These same holes, however, are too small to accept N2 or Argon.

Weatherford says the service is ideal for remote locations or regions where cryogenic nitrogen is limited or disruptive in supply.

Comments