March 2010 Vol. 237 No. 3

What's New

March New Products

New products and innovations from Lincoln Electric, Wasco Energy and Deepwater Corrosion, GE Sensing & Inspection, BJ Services, R&M Energy, BS Coatings, Dresser, Applus RTD, Mokveld Valves BV, MSA and TechCorr.

Lincoln Electric

Lincoln Electric has added a second series to its popular line of Viking™ auto-darkening welding helmets. The existing 700G Series and new 750S Series helmets are solar-powered, lightweight and fully loaded with a variety of features and accessories. These helmets are lighter in weight than many auto-darkening helmets. The 700G Series weighs 18 oz. and the 750S Series 19 oz. Both use a solar-power system, making it unnecessary to remember to switch a power control on or off or replace batteries. Both series feature robust headgear with a soft, absorbent sweatband; a grind mode for weld prep and post-weld clean up; solar-powered systems with battery assistance on-and-off capabilities; a free welding helmet bag and Tribal pattern bandana; fast lens switching speeds of 1/25,000 sec.; and low TIG amp ratings of DC < 3="" amp;="" ac="">< 5="" amp.="" www.lincolnelectric.com,="" bulletin="" e12.207.="">Wasco Energy Ltd./Deepwater Corrosion Services Inc.

Wasco Energy offers a brochure on is website that, among other products and services, points to its established American company, Deepwater, that delivers specialized and innovative systems for offshore corrosion problems using its in-house knowledge foundation and advanced products. The Houston-based company’s ideas and unique product design and application are said to provide practical solutions to corrosion problems. Deepwater aims to be a complete center for offshore corrosion protection and solutions for new construction and retrofit applications. Among the products listed are galvanic anode solutions, impressed current solutions, Polatrak CP monitoring systems and pipe-support systems. Services offered include pipeline inspection services (CP Snake, SunStation CP and SubSpection), corrosion consulting services and offshore topside and subsea inspection services. www.wascoenergy.com. www.stoprust.com.

GE Sensing & Inspection Technologies

GE Sensing & Inspection Technologies offers the DXR250V portable, digital radiography tool. Weighing 13 lbs., it is the latest lightweight tool to be offered by the company which says in the past, the use of digital radiography (DR) has been limited due to size, weight and connectivity of the equipment. With the new tool, DR users have the benefit of shorter shot times and minimal radiation exposure in applications that were previously limited to computed radiography or film. The company says the tool can easily connect to a laptop computer and produce images for instant review with GE’s Rhythm® software, providing gains in productivity. Key applications include field inspections in the oil and gas, aerospace and power generation sectors. www.gesensinginspection.com.

BJ Services Company

BJ Services has introduced the GEMINI™ system, described as a range of combo tools that provide caliper, metal loss and mapping information in a single tool. The company says in response to customer demand, its pipeline inspection services group embarked on an ambitious campaign to develop and deploy the GEMINI combo tools, integrating existing technology and customer benefits found in the fleet of GEOPIG™ and VECTRA™ tools. Unlike conventional combo tools, the new tool uses an active speed control with a gas bypass capability to run in high-speed gas pipelines to obtain corrosion and deformation information without restricting gas flow or line speed, a feature common to the VECTRA magnetic flux leakage (MFL) metal-loss tools. Drawing from company sites in Calgary, Houston and Pescara, the tool-development team worked to meet a four-month deadline. To date, BJ has completed multiple inspections in high-speed gas pipelines with the GEMINI tool for TransCanada Pipeline, ANR and Alliance Pipeline in the United States and Canada. Andrew Staszewski, 403-531-5446, Email: astaszewski@bjservices.ca, www.bjservices.com.

R&M Energy Systems

R&M Energy Systems offers its latest, most technically advanced solution for pipeline and vessel closures. Marketed under the SENTRY® brand name, the non-threaded, internal door closure now features an innovative one-piece seal that is said to provide many features and benefits that are not available in other types of closures. Some features include molded in all sizes with no vulcanized splices; available in FKM (Viton), EDR FKM (Viton) or HNBR low-temperature materials; installation of the one-piece replacement seal is quicker and easier than ever; and an anti-extrusion spring is molded into the seal. All pressure-retaining components are manufactured from ASME SA-designated materials. An improved hinge arrangement and a unique means of holding the locking segments in the open position make operation easy. The method of securing the closure’s locking components to the door helps prevent the possibility of injury during pipeline or vessel servicing. 403-264-2995, 936-890-1064, info@rmenergy.com, www.rmenergy.com.

BS Coatings

BS Coatings has introduced what it describes as an innovative Silpipe® application process that says ensures good adhesion of fusion bonded epoxy coatings for the external protection of pipelines, whether used as a primer for multi-layer coatings or alone as a mono-layer coating. The company says the patented process involves the deposition of a silane-based solution specifically formulated for the chemical surface treatment of steel pipes as a “technical environmentally friendly” alternative to the toxic substances used at present for chemical surface treatment. The company claims its process solves two problems: optimizing the adhesion of single-layer or multi-layer primer FBE powders to steel pipe, especially in hot and wet environments; and providing a new technology that has no VOCs or toxic waste and no hexavalent chromium. The solution is commercially available under the Silpipe® SCT trademark. Pascal Collet, 33-2-32-77-30-77, collet@bs-coatings.com, www.bs-coatings.com.

Dresser

Dresser offers a flyer devoted to its regulator with added capacity port. Dresser says its 2-inch AC Port Flowgrid® Regulator is designed to be used in conjunction with a self-contained pilot control system. Dresser presents the case for its expanded capacity 2-inch regulator that aims to help natural gas engineers get more flow with low regulator outlet velocity. The company says this Flowgrid Regulator is an economical and easy-to-maintain pilot operated valve for gas and liquid applications. It ideal for skid-mounted, vault and enclosure installations. Its valve combines a 2-inch body with a 3-inch port, providing a Cg value of 1970. The Flowgrid Regulator is bi-directional and has a full ANSI rating on the inlet and outlet (CL150, 300, 600). The flyer includes specifications, materials of construction, flange dimensions, flow coefficients and constants, diaphragm selection, minimum pressure differential vs. capacity, and stock numbers. 801-487-2225, www.dresser.com/mooney.

Applus RTD

Applus RTD has introduced what it terms breakthrough technology that enables real-time digital radiographs by scanning along girth welds like AUT. Applus says this technology surpasses all competing devices in quality and speed, including the “notorious” film quality threshold. The company says key results during verification of the technology were that all images fulfilled ASME V and API standard 1104 20th ed. 2007; all images fulfilled EN1435/ISO17636/DNV )OS F101 Class A; and Class B is reached with slower scan speeds. 832-295-5000, www.applusRTD.com.

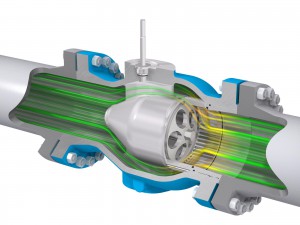

Mokveld Valves BV

Mokveld Valves BV, The Netherlands, says it has been an innovative supplier of engineered valve systems since the 1950s and now offers a subsea axial control valve. The company says, with the axial flow valve concept, it has gained a unique position in the severe service market. Axial refers to the streamlined symmetrical and unrestricted flow path between the valve inner and outer body. Cooperating with subsea integrators Oceaneering, FMC and Aker Solutions, Mokveld says it has developed and qualified an 8-inch/API 5,000 subsea axial control valve. The qualification program included an API 6A PR2 test, endurance testing with 500,000 cycles and hyperbaric-testing simulating seabed conditions. Two valves have been delivered for the Ormen Lange Subsea Compression and the Åsgard Minimum Flow Qualification Projects for severe service anti-surge control applications. 31-182-59-75-00, email: marketing@mokveld.com, www.mokveld.com.

MSA

MSA has released an application note concerning a new monitor for fuel leaks. The Chemgard Photoacoustic Infrared Monitor is described as ideal for monitoring fuel leaks in refinery engine test and fuel-blend rooms. It is described as being excellent for detecting gasoline and other fuel vapors in this application due to its ability to detect low ppm levels. A multi-point system with strategically located sample points can be used to cover a large room area. www.msagasdetection.com, www.msanorthamerica.com.

TechCorr

TechCorr says its SpiderWrap® is for such pipe wrap uses as reinforcement, corrosion protection, abrasion protection, impact protection, and – in certain instances – leak repair. It is a water-activated, resin-impregnated fiberglass fabric made in varying lengths and widths to accommodate all pipe sizes and wall thicknesses. It is nontoxic, easy to apply and suitable for a variety of pipeline applications. The company says it is a fast, efficient, economical alternative to any other repair product or replacement. In most applications, the need for pressure reduction is minimized and downtime is eliminated. 713-524-2768, 877-562-0912, www.techcorr.com.

Comments