December 2008 Vol. 235 No. 12

TechNotes

Using PD Screw Pumps To Move Crude Boosts Efficiency And Reduces Emissions

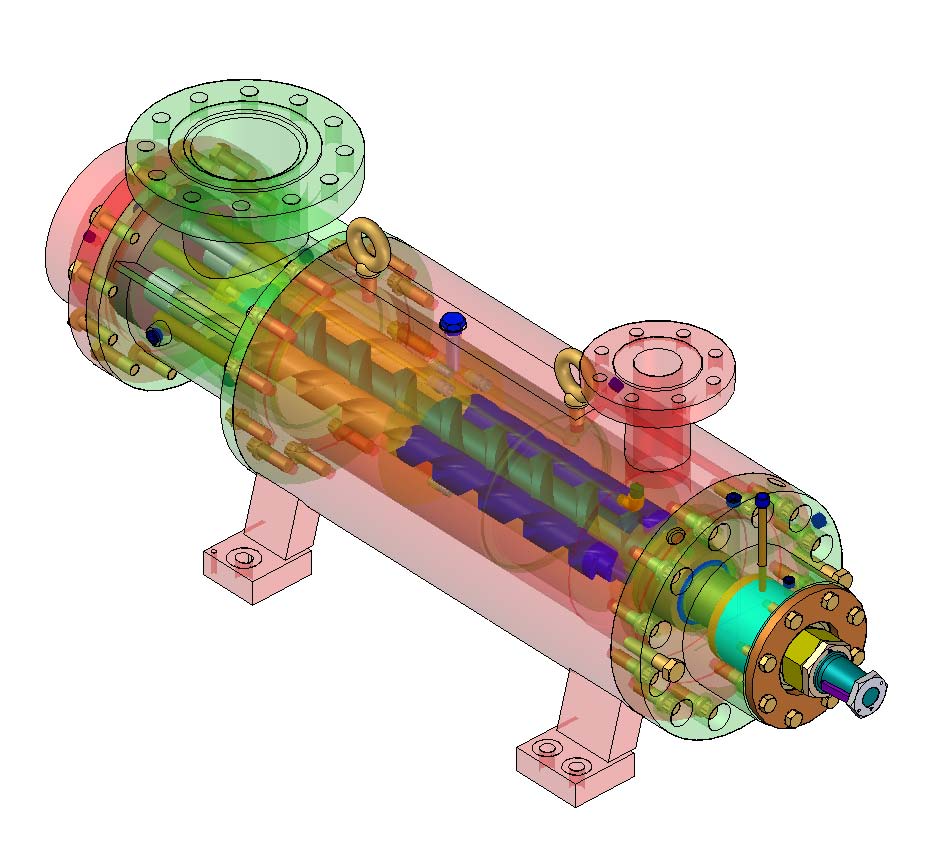

Colfax Corporation says its line of rotary positive displacement (PD) screw pumps moves crude oil reliably while responding to growing industry demand for higher energy efficiency and greater environmental responsibility.

“Rotary pumps have been the standard in delivering high-efficiency, low-maintenance solutions for critical fluid handling in the past,” said John Young, president/CEO. “The perception that screw pumps mean higher expense is simply outdated, preventing oil transport companies from taking full advantage of their significant benefits for energy savings and reduced environmental impact in these applications.

“In fact, rotary PD screw pumps offer tremendous cost advantages,” he continued. “A typical solution on a single 250,000-bpd crude oil pumping station in western Canada – using three rotary PD screw pumps operating in parallel with one standby pump – delivers a 29% reduction in combined capital, energy and maintenance costs over a five-year period, when compared to the traditional centrifugal pump solution of two pumps operating in parallel with one standby pump. That translates into more than $7 million in savings to own and operate a rotary PD screw pump solution over five years, a concept that we call Total Savings of Ownership.”

“We’ve also taken the lead in developing various shaft-sealing solutions, for the industry to address market demand for reduced process fluid emissions,” Young noted. “Like the rotary PD screw pump designs, they are efficient and reliable, providing operators with the highest level of safety.”

According to Mike Moore, a Colfax product specialist in crude oil transport, western Canada recognized early on the advantages of the screw pump’s simple, but robust design. “Oil companies have used screw pumps to move crude oil to market for the past 30 years; and in Alberta and Saskatchewan, screw pump lines manufactured by Colfax handle 4.8 million barrels of crude oil each day,” he said.

Moore said the hydraulic principle behind screw pump operation delivers both high volumetric and high overall operating efficiencies in addition to offering long mean time between repairs (MTBR) and ease-of-maintenance features for field servicing, which combine to maximize operational uptime. Other advantages of these pumps cited by Moore include:

- Constant flow, even in the presence of varying system backpressures.

- Non-pulsating flow, without the need for pulsation dampeners.

- Low noise and vibration levels, minimizing foundation requirements.

Comments