January 2019, Vol. 246, No. 1

Features

Growing Role of Digitalization in Pipeline Integrity Management

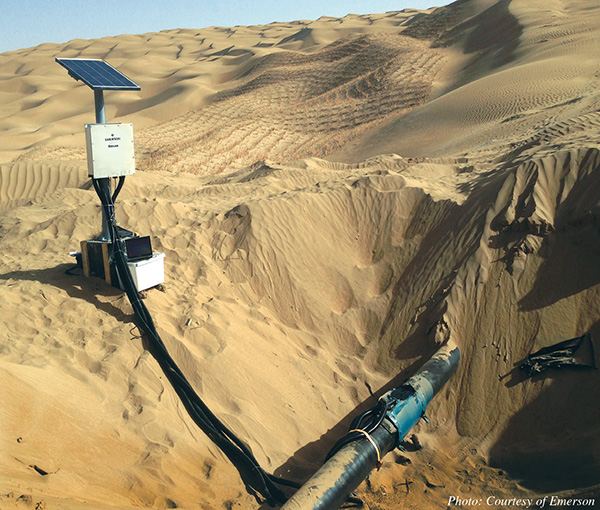

By Ivan Stubelj, Emerson Automation Solutions

When it comes to the safe transportation of gases and the integrity of pipelines, the ability to operate such infrastructure in a safe and reliable manner is vital.

Yet, pipelines today consist of vast and complex networks, delivering from remote locations to gas processing facilities and petrochemical manufacturers. The number of pipelines in remote areas is also adding to the challenge, with approximately 2,175,000 miles of pipelines in 120 countries around the world and – according to Pipeline & Gas Journal’s 2017 Worldwide Pipeline Construction Report – 83,000 miles of new pipelines planned.

This article will look at pipeline integrity management – in particular, relating to the threat of internal corrosion – and the growing role of digitalization.

Integrity Threats

Pipeline operators in the United States are required to abide by regulations from the Pipeline and Hazardous Materials Safety Administration (PHMSA) and two widely accepted standards: ASME B31.8S and ASME 2012c.

These standards identify three key threats to pipeline integrity:

Stable, resident threats – threats that don’t change over time, tend to be influenced by another condition or failure mechanism, and cover areas such as manufacturing and construction.

Threats that are time-independent and could be down to human error or outside factors, such as weather.

Time-dependent threats – threats that grow over time and include external corrosion, stress corrosion cracking, and internal corrosion.

In a 2016 National Association of Corrosion Engineers (NACE) impact study1, the global cost of corrosion was estimated at $2.5 trillion. According to PHMSA, corrosion was responsible for 18% of significant pipeline safety incidents (both onshore and offshore) in the 20-year period from 1988 through 2008, with 40 to 65 significant corrosion incidents per year2.

The same issues also can be seen in Canada where the Alberta Energy Regulator (AER) in its 2018 Pipeline Performance Report3, found internal corrosion to be the leading cause of pipeline failures, representing 37% of such failures in 2017 and 92% of high-consequence incidents occurring on pipelines that carry corrosive substances, such as salt water or oil well effluent.

Traditional Assessment

So how are operators addressing internal corrosion? The traditional means of combating corrosion include pipeline integrity management (PIM) frameworks that consist of process-oriented, performance-based programs and start with hazard identification and hazard and operability analysis (HAZOP) – qualitative methods that examine the pipeline for possible hazards.

Building on these are a few integrity assessment methods that include in-line inspection (ILI) and direct assessment.

ILI covers a wide variety of tools and techniques, such as ultrasonic inspection, magnetic flux inspection, metal loss tools and pigging. While effective, ILI, however, comes with challenges, such as the need to have pipelines configured and specification requirements.

There are also operational and cost issues, such as pipeline shutdowns and extensive planning and execution requirements, and the fact that pigs can only handle a few miles on average, require multiple launches, and cost as much as $35,000 per mile.

Direct assessment consists of external corrosion direct assessment (ECDA), internal corrosion direct assessment (ICDA) and stress corrosion direct assessment (SCCDA). It has limitations as well, such as short pipeline sub-segments coverage and the fact that data from a few select locations along the pipeline is used to characterize the integrity of the entire pipeline. In addition, there are hydrostatic pressure tests (HPT) – with measurement intervals that range from months to years and provide only isolated snapshots throughout the pipeline’s lifetime.

Furthermore, despite the time-dependent nature of corrosion, current threat assessment methods fail to track corrosion on a continuous basis. Aging supervisory control and data acquisition (SCADA) systems, the diverse nature of pipeline asset and integrity data, and the various ways of gathering and reporting it can make the process of transforming data into actionable information extremely difficult.

For instance, a field report of a leak may give its location using GPS coordinates, while an ILI may provide a different location of pipe wall corrosion using an odometer reading.

Likewise, data is often located across different parts of an organization with the corrosion engineer needing to integrate such data to perform the risk assessment and yield the proper integrity management recommendations and conclusions.

It’s against this backdrop that there is a growing move toward digitalization in fighting internal corrosion. Improvements in operational performance will require better data integration, more sophisticated data analysis, and better ways to visualize information. The rest of this article will examine how this is being achieved.

Growth in Digitalization

Digitalization is becoming more prevalent in the pipeline sector, with companies embracing digital transformation as a crucial component of pipeline management tools for monitoring, predicting, and planning for the future.

Take the growth in real-time sensors. In-line sensors, such as electrical resistance (ER) probes, electrochemical probes and corrosion coupons, play a key role, alongside other technologies, in providing real-time corrosion data.

Probes provide the highest sensitivity and fastest responses to changing corrosion rates and are most commonly used for uniform corrosion measurement or detection of changed fluid corrosivity. As an example, a 20 mi element probe can detect a corrosion rate of 5 miles per year (mpy) – defined by NACE International as moderate to severe – within hours and less than a day, depending on measurement frequency.

The high sensitivity and the digital technologies around them make probes valuable for the fast-track monitoring of process changes and for tuning processes, such as corrosion inhibitors.

When it comes to non-intrusive measures, options include wall thickness monitoring via ultrasonic (UT) measurements. Installation of UT sensors permanently on the pipe (clamped or stud-welded to any pipe section or asset) provide real-time regular measurements on the spot, increasing stability and sensitivity. Real-life sensitivity for UT measurements is typically 10-20 micrometers for changes in wall thickness and it is also possible from the form of the wave signal to determine surface conditions inside the pipe. Again, advanced data analytics can help detect the weak points of a system.

One of the most significant corrosion monitoring technologies when it comes to the growing digitalization of pipeline integrity management is the field signature method (FSM). FSM is based on feeding an electric current through a monitored section of a pipe, pipeline or vessel. The applied current sets up an electric field that is monitored as voltage drop values between a set of sensing pins installed on the external pipe wall.

The initial measurement sequence measures the voltage drop between all pairs of sensing pins and is called the field signature. Later measurements are compared to the field signature, in which general corrosion is a uniform increase in voltage drops between all pin pairs and localized corrosion is an increase in the values.

FSM data can then be plotted as metal loss over time for the efficient tracking of changes in metal loss or in 3-D plots that show the distribution of corrosion over the monitored area. Typical sensitivity for FSM is 0.1% of wall thickness for general corrosion, corresponding to 10-20 micrometers in most cases.

While the technology has been available for up to two decades, FSM is seeing greater digitalization. Emerson, for example, has developed the Roxar FSM Log 48 Area Corrosion Monitor, a new pipeline integrity management tool that delivers permanent, cost-effective and online area corrosion & erosion monitoring for remote and large area pipelines.

The monitor, which consist of 48 pins in the sensing pin matrix, is a variant of the already established potential drop technique and monitors a pre-defined area with the ability through the sensing pins to distinguish between localized corrosion and generalized corrosion.

As part of integrated digital pipeline integrity management, Emerson has also developed a data management solution that can interface with supervisory control and data acquisition (SCADA) systems through Modbus TCP/IP, providing advanced data trending capabilities, alarm setting, and information sharing options. It is this information sharing that can increase pipeline integrity and optimize pig runs (when pipe bends, valve restrictions and contaminant build-up are restricting pigs from moving through pipelines), integrity digs and hydrostatic pressure tests.

This continuous digital monitoring of general and localized internal corrosion allows early threat identification and improved risk assessment, and avoids unnecessary pipeline shutdowns, costly hydrostatic pressure tests, and repairs due to leaks.

Conclusions

There is no doubt widespread digitalization still has a way to go – 70% of pipeline leaks are still identified only by visual inspection.

What is clear, however, is that successfully deploying a digitalization strategy in pipeline integrity management can play a crucial role in fostering proactive data-driven decision-making and deliver substantial gains to the bottom line. P&GJ

Author: Ivan Ruiz Stubelj is a product manager for non-intrusive corrosion and erosion monitoring technologies at Emerson Automation Solutions.

Comments