January 2012, Vol. 239 No. 1

Features

Mastering Construction Challenges In The Sahara Desert

The challenges and complexities of building oil and gas infrastructure in a remote and inhospitable part of the Sahara Desert are adding to the stores of knowledge possessed by ABB engineers and technicians.

Over the past 45 years, ABB has completed more than 300 engineering, procurement and construction (EPC) projects in the oil and gas, power generation and water industries. Many of these projects are located in remote and demanding environments where the logistical constraints of deploying equipment, materials and labor across multiple work-fronts are a major challenge.

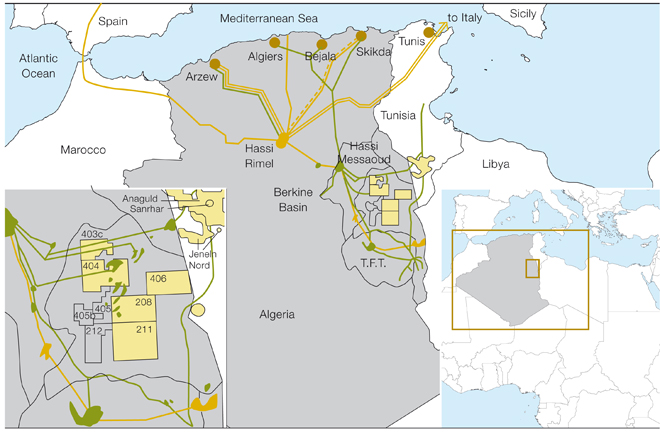

One such project is the El Merk oil and gas field in Algeria, for which ABB is designing, procuring, constructing and commissioning a significant part of the field infrastructure. Located in a remote corner of the country, El Merk is a vast and searing desertland of towering, intermeshing sand dunes that stretches across an area of some 1,930.5 square miles (5,000 square km). The sheer expanse and complexity of El Merk demands a unique set of EPC skills and tools to ensure that implementation and completion are on time and on budget.

The El Merk oil and gas fields are situated in the Berkine Basin, the second-largest hydrocarbons basin in Algeria and one of the most prolific in the country in terms of output and the frequency of new discoveries. Located in the depths of the Sahara Desert, El Merk is a harsh and inhospitable environment. Temperatures frequently reach 122 degrees F (50 degrees C), rainfall is negligible and the terrain is largely composed of huge interlocking sand dunes, which tower to a height of 984.25 feet (300 m) and whose contours are constantly shifting in the burning dry wind. It is also a remote environment, with no previous infrastructure and a long 621.37-mile (1,000-km) journey to the cities and ports of the northern coastal belt, where 90% of Algeria’s 35 million inhabitants live.

El Merk consists of four oil and gas fields – EKT, EMN, EME and EMK – which together make up a concession known as Block 208. All four fields are being developed by the Sonatrach-Anadarko Association and partners, which is jointly owned by Sonatrach (the Algerian state-owned oil and gas company) and Anadarko, a Houston-based independent oil and gas company.

When fully operational in 2017, El Merk will produce 150,000 barrels of oil equivalent a day from 138 wells. The wells will be linked by a system of field pipelines to 10 field gathering stations (FGS) and six gas distribution manifolds (GDM), from where it will be piped to a central processing plant for separation, stabilization, gas compression, natural gas liquid extraction and storage. Eighty of the wells are to be drilled, hooked up and producing in 2012.

ABB’s Responsibility

Sonatrach-Anadarko has awarded several EPC contracts for El Merk and has drawn up a tight and challenging schedule for the construction and completion of the project. Different EPC contractors were selected for the central processing facility, and a number of other international and local contractors for the camp accommodation (base de vie) and industrial base, and for the export pipelines, power lines and substation. The ABB-led consortium comprising Sarpi of Algeria and PetroJet of Egypt is responsible for the offsite facilities.

ABB was awarded the EPC contract for the offsite facilities package (lots 3 and 4) in 2009. The contract is worth U.S.$650 million and is one of the largest EPC contracts in ABB’s history. ABB is responsible for the design, procurement, transportation, construction, commissioning and startup of the 10 field gathering stations, six gas distribution manifolds, the complete material supply for 120 wells as well as for hooking up the first 80 for production in 2012, and 446.76 miles (719 km) of pipelines and process piping across all four fields in the El Merk concession. ABB’s scope of supply includes 1) the water systems for injection; 2) the flowlines for production, gas lift, dilution water and water supply; 3) the trunklines for oil and gas condensate, gas injection and water injection; and 4) the process piping.

In terms of equipment and products, ABB’s responsibility encompasses water injection pumps, source water booster pumps, dilution water pumps, water filters, recycle coolers and nitrogen separators. On the electrical side it includes medium and low voltage switchboards and power transformers; and in instrumentation it comprises the metering system, multi-phase flowmeters, wellhead valves and field instruments. The chemical injection skids, pipeline pig launcher and receiver stations, and cathodic protection systems are also within ABB’s area of responsibility.

GIS Precision

Another key ABB deliverable is the geographic information system (GIS) for the entire El Merk project. The GIS is a geospatial-based infrastructure management system that enables all the field infrastructure and production assets to be designed, constructed, maintained and managed at the highest level of efficiency. It provides all participants in El Merk with an accurate and up-to-date view of the progress of the project in real time. It integrates data coming from many different sources and performs precise calculations of the amount of material needed for construction. It assesses all possible interferences along the pipeline corridors, such as differences in elevation, the angle of dune slopes, and so on. And it automatically generates alignment sheets and documents, including all information needed in the field. The solution supports the pipeline open data standard (PODS) model, the most widely used pipeline data model in the oil and gas industry.

The GIS is the key to the success of a major infrastructure project like El Merk, where there are numerous EPCs and subcontractors and thousands of workers involved at any one time. Without it, the development of El Merk would likely take an additional 12 months, with all the added costs and revenue loss that such a delay entails. For instance, in a project of this scale it is not unusual for the location of wells or the route of pipelines to change as construction and deployment progress. Because subcontractors tend to interpret geodetic data differently, disagreements as to the correct positioning of production assets are common. The ABB GIS solution eliminates these inefficiencies and potential sources of delays. It brings precision and efficiency to a field that was previously open to misinterpretation and error.

ABB selected Intergraph as its partner in the GIS project, with Intergraph supplying the geospatial platform and ABB managing the project information and interfacing the data from all the EPCs and contractors. Figure 4 shows the extent of the infrastructure construction data that the GIS manages. The system monitors the construction of every single site asset – from the wells and pipelines to the shops, offices and housing on the base, and the power lines, utilities and communication cables that link the assets into a network.

Meeting Complex Challenges

El Merk is a highly complex and challenging project that requires the EPC to possess a unique set of skills and experience. The fields are spread over a wide area and the wells are being drilled at the same time as the pipelines are being laid and the facilities constructed.

Up to 6,000 personnel will be working on the project at its peak. Recruitment is far from easy as there are many other projects in Algeria competing for the same skills and personnel. Language barriers and cultural differences in a community of this size are common; they have to be planned for and managed. Security is also an issue – expatriate workers require military protection and escorts at all times.

On the logistics side, huge volumes of equipment and materials have to be ordered from suppliers and factories all over the world. The equipment has to be tested, quality assured and inspected, and able to operate in temperatures of 131 degrees F (55 degrees C). Orders have to be expedited and closely monitored, shipped to ports in Algeria, and transported by truck on a two-day journey through the desert to El Merk. Importation regulations have to be complied with, port and custom authorities dealt with to ensure there are no delays in customs clearance. And, the arrival of incoming goods and materials has to be coordinated to make warehousing and truck transportation efficient, cost-effective and on schedule.

To implement the project, ABB estimates that it will spend 150,000 man-hours on procurement and project management alone, and a further 200,000 man-hours on engineering. An ABB site team will supervise the field activities of the almost 2,000 people that its partners Sarpi and PetroJet employ onsite. This workforce is expected to spend 5 million man-hours building and installing lots 3 and 4 over the course of some 42 months.

With regard to hardware, the ABB consortium is responsible for designing, delivering, installing and commissioning some 435 miles (700 km) of pipeline, which will be fitted with almost 10,000 manual valves. ABB’s electrical scope includes 186.4 miles (300 km) of high voltage cables, 124.2 miles (200 km) of low voltage cables, more than 150 high, medium and low voltage switchboards, and 140 transformers. Instrumentation includes 3,000 field instruments (control valves, transmitters, pressure gauges, flowmeters, etc), 248.5 miles (400 km) of instrument cables and 248.5 miles (400 km) of fiber optic cables. And ABB is also responsible for five telecom towers and the HVAC (heat, ventilation and air conditioning) and fire fighting systems at the ten field gathering stations.

Zero-incident HSE

With a workforce of 1,500 people working several million man-hours, the need to excel in HSE (health, safety and environment) is a crucial aspect of ABB’s responsibility. ABB’s overall HSE objective can be summarized in a few short words: 1) no harm to people, 2) no damage to the environment, 3) no damage to property, and 4) no loss or damage to data and documents.

ABB’s HSE targets for El Merk are to instill a zero-incident culture throughout the workforce, design HSE into all consortium facilities and worksites, develop and implement an HSE management system and risk management process, implement site-specific HSE plans and programs for contractors, and have in place operational readiness for a seamless handover of HSE procedures and systems upon project completion.

EPC Center Of Excellence

ABB is directing the El Merk project from its EPC center of excellence in Milan, Italy. Over the past 45 years ABB has completed more than 300 EPC projects in the oil and gas, power generation and water industries worldwide. Its extensive portfolio of completed and ongoing projects makes it one of the most experienced and successful EPC contractors in the business. Many of these projects are located in remote and environmentally hostile regions where the logistical constraints of moving equipment, materials and labor to multiple work-fronts are a major challenge.

ABB’s long and successful track record in oil and gas EPC projects is combined with a strong local presence in Algeria that dates back to the 1970s. The continuous involvement of ABB in the growth of the country’s oil and gas industry led ABB to form Sarpi, a joint venture with Sonatrach, in 1993.

Other EPC projects in Algeria that ABB is currently implementing include a gas-flaring elimination project at Haoud Berkaoui on behalf of Sonatrach (the contract is valued at $225 and covers gas compression trains and re-instrumentation at three sites); and the delivery of utilities, storage and export facilities for the central processing plant at MLE in the Berkine Basin (a contract worth $245 million). Contact the author: sergio.casati@it.abb.com.

Comments