March 2009 Vol. 236 No. 3

Features

Applying APDM To Pipeline Integrity Management At Petrochina

PetroChina began its pipeline integrity management (PIM) project in 2005. As the project progressed, officials realized the structure of the pipeline data model formed the basis for many kinds of analysis and assessments increasingly important to an operator when implementing PIM.

Petrochina needed a data model to store and organize pipeline data in a database to implement PIM. The company chose ArcGIS Pipeline Data Model (APDM). For the moment, the Geodatabase is built up by this model to manage data from more than 10,000 km of PetroChina pipelines and is providing data support for many kinds of analysis and assessment.

Four data models are available. They are the Pipeline Open Data Standard (PODS), the ArcGIS Pipeline Data Model (APDM), the Integrated Spatial Analysis Techniques (ISAT) model originally developed by Gas Research Institute, and the European Commission-funded Industry Standard Pipeline Data Management (ISPDM) project. Most operators now choosing a data model select either the PODS or the APDM, which this article will focus on.

PODS Pipeline Data Model

The PODS model began with PODS 2.0 released in 2001 as a modest set of less than 70 tables. PODS 4.0.1 was released in May 2007 with hundreds of tables. The current model includes tables for pipe location, pipe facilities, geographic features, inline inspections, cathodic protection, close interval surveys, physical inspections, integrity management data, offline events, and more. PODS is:

- A comprehensive pipeline data model;

- Primarily used for operations and integrity management but includes all areas of information related to a pipeline;

- Designed for gas and liquids;

- Designed for gathering, distribution, and transmission lines;

- An open standard;

- The intellectual property of the PODS Association; and

- Designed by PODS members – industry leaders who volunteer on the technical committee and on working groups.

APDM Data Model

Initial work on the APDM model was started by M.J. Harden in 2002 and APDM 1.0 was released in July 2003 at the ESRI International User Conference in San Diego, CA. The final version of APDM 4.0 has now been released, including 21 core classes, two metadata tables, 23 abstract or template classes and 102 example classes. APDM is:

- A comprehensive pipeline data template managed by APDM/PIG;

- Designed for management of a pipeline centerline to support facility, integrity and operational management;

- Designed for gas or liquid systems;

- Designed for gathering, distribution and transmission lines;

- An open template;

- The intellectual property of ESRI; and

- Designed by APDM Technical Committee.

Similarities And Differences

APDM and PODS are not competing models; they simply offer operators different options to meet the needs of their organizations. The APDM and PODS models have been specifically designed for the pipeline industry and each is appropriate for deployment in a transmission or gathering environment. There are similarities between the models, including that they:

- Support similar types of pipelines – transmission and gathering, liquids or gas;

- Support use of linear referencing and absolute coordinates to locate features;

- Are run by technical and administrative groups comprised of operators, consultants, and vendors;

- Are GIS capable;

- Select solutions from a group of vendors; and

- Blend solutions for multiple vendors.

The differences between the models include the following:

- APDM is a template with a standard core, which is not approved by any industry body but must be implemented as described in order to promote maximum interoperability between database implementations and business partner software;

- PODS is a certified standard that seeks to define in rich detail the features that describe a pipeline, and the entire PODS tables structure is meant to be implemented “as is” – this is what comprises the standard;

- PODS describes in extensive detail the content and structure of a pipeline database while APDM describes in extensive detail the behavior of pipeline data elements when they are edited;

- APDM is an ESRI Geodatabase, and therefore has GIS built into the model. Its implementations are standard and generally involve the same types of technology (linear referencing/topology), while the PODS model is a Relational Database Management System with no inherent GIS functionality. It stores linear referencing and coordinate information in tables.

Where we can draw a conclusion, the PODS model is vendor neutral and offers pipeline operators the ability to choose the most appropriate GIS application for their organization. APDM provides an operator with flexibility but is open-ended. In order to customize and implement the model, the operator needs a good understanding of his or her business needs. APDM is an ESRI Geodatabase; an enterprise Geodatabase is an object-relational database management system. The standard technologies used to access data in a RDBMS such as Structured Query Language (SQL), Open Database Connectivity (ODBC) or Microsoft ActiveX Data Objects (ADO) are not designed to access data stored in a Geodatabase.

The primary method for customizing and accessing the data stored in the APDM is through the core ESRI ArcGIS technology (such as ArcMap) and its underlying component model, ArcObjects. This is not to say that all SQL-related functions will not perform against a Geodatabase, rather, the applicability of SQL is limited. And, users need to be aware of the potential impacts to the underlying Geodatabase when attempting to perform insert, update and delete operations using standard database access techniques (especially when the Geodatabase is in a versioned state).

Why did Petrochina choose APDM? ESRI products have long occupied a large share of the Chinese market. In 2006, that share was estimated at more than 70% of Chinese GIS software market. APDM – as a standard model published by ESRI – has defined a core set of standard tables and behaviors that are required, and the rest of the model is only modeling the relationships for event types (line, points and polygons).

Although PODS describes in extensive detail the content and structure of a pipeline database, it also includes many items of content which are not in accordance with actual requirements of PetroChina, such as U.S. regulatory compliance. PODS ESRI Geodatabase was proposed in early 2007, but remains in its formative stages. What’s more, PetroChina engineers can be aware of actual requirements of PetroChina pipeline and can build the Geodatabase by using Case Tools. PetroChina PIM also needs to define the content and structure of its table according to its own requirements. APDM is the best choice for PetroChina based on the current situation.

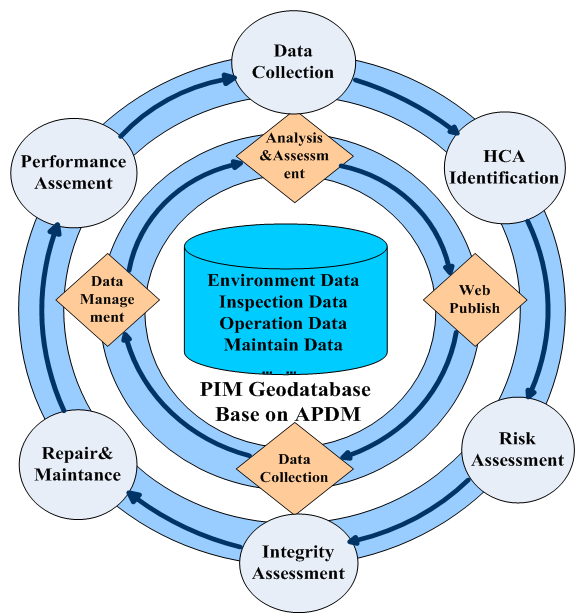

APDM is not a “standard” in the traditional sense. It is a template that requires specific core classes to be implemented in a standardized fashion and intentionally designed to allow for extendibility. This provides operators with flexibility to customize their own requirements. Petrochina extends APDM published at ESRI’s Website according to its actual requirements of PIM and classifies related pipeline data into 11 parts such as Centerline, Cathodic Protection, Encroachment, Operation, Facility, Event Support, Inspection, History, SheetGen, Risk and Landbase. Figure 1 shows working procedure circulation and data flow circulation of PIM.

Figure 1: Working procedure circulation and data flow circulation of PIM.

Figure 2 shows PetroChina’s PIM software system architecture based on APDM. As the PIM software system architecture shows, PetroChina develops a series of software units to implement PIM.

Application Of APDM

The second software layer includes data collection and data management software. Data collection is the basis of other work of PIM. The standards of data collection for PIM shall be determined once APDM is customized by PetroChina. It should be in accordance with enterprise related to data standards as much as possible to facilitate interoperability among other systems.

PetroChina’s historical pipeline data storage cannot satisfy the requirements of PIM. For example, data documented on paper including as-built sheets, operation records and inspection reports and preserved separately in subsidiary companies cannot satisfy PIM requirements.

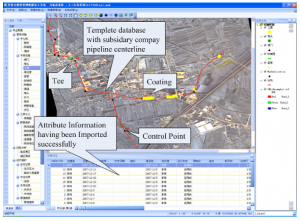

APDM can integrate, organize and store these historical data into a Geodatabase to meet requirements of PIM, thus PetroChina needs software based on APDM to collect pipe data. PetroChina customizes its contents and standards of data according to requirements of PIM, and develops the data collection software. Figure 3 shows collection data by data import software. At the beginning of a project, a PIM Geodatabase needs to be built.

Subsidiary companies shall collect pipeline data by the data collection software and the template database with subsidiary companies’ pipeline centerline released by headquarters, and then submit the completed local Geodatabase to DBA in the headquarters. The pipeline data from the subsidiary companies is checked before being imported to the PIM Geodatabase.

Figure 3: Data collection software.

Data Management

It is well known that data accuracy is an important requisite for all kinds of analysis result. In fact, data management software ensures accuracy and integrity by editing data and managing relationships between tables in Geodatabase. Pipe data assigned coordinate location or station values shall be stored in Geodatabase at the shape of point, line and polygon. However, in the daily management, it happens often that coordinate location or station values are modified because of the activity of pipeline re-route.

APDM describes in extensive detail the behavior of pipeline data elements when they are edited, especially when pipeline centerline location and station values are modified. What’s more, these behaviors and regulations have been integrated into APDM core classes. As a result, users can manage easily their own data by using these behaviors and regulations. Figure 4 shows that data management software developed based on APDM can manage, when a pipeline is re-routed, the station value of the control points and online features of pipeline center line.

Figure 4: Data management software.

HCA Analysis

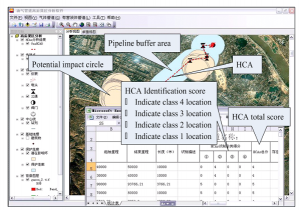

Once a high-consequence area (HCA) is identified, operators are required to devote additional focus, efforts and analysis to ensure the integrity of pipelines in the area. In the past, data were collected manually on site for HCA analysis. That was costly, time-consuming, and the accuracy of the results was uncertain. Now, these data can be managed by the PIM Geodatabase and the coordinate location can be managed precisely using GIS technology.

For example, when performing HCA analysis, PetroChina needs to survey the data surrounding pipeline-like structure, population density, road, railroad, hydrology and inspection. These features and related attributes can be defined directly into the APDM at the beginning, according to the requirements of the HCA analysis. Figure 5 shows the company’s Lanchengyu pipeline HCA analysis result.

Figure 5: HCA analysis software.

Risk Assessment

Risk assessments are the very foundation of an integrity-management program. The ultimate goal of assessing risks is to identify the most significant so that an operator can develop an effective and prioritized prevention, detection and mitigation plan. The research on risk assessment and development of practicable risk-assessment methods are very significant and necessary. Risk assessment in PetroChina is at the beginning phase so PetroChina bought some international software like Pyramid, GE PVI and DNV Orbit. Fortunately, APDM can be customized according to the data required by the software. It can directly export the necessary data from PIM Database for offline assessment. Figure 6 shows the result of risk assessment by Pyramid for the Petrochina Lanchengyu pipeline.

[inline:PetrochinaFig.6.png=Whole pipeline assessment result by Pyramid for the Petrochina Lanchengyu pipeline.]

Figure 6: Whole pipeline assessment result by Pyramid for the Petrochina Lanchengyu pipeline.

Web Application

The aim of PIM is a pipeline that can be in a controllable safe state. With its many kinds of software-produced analyses and assessment results, a user interface is needed to display pipeline data to instruct related departments to implement pertinent pipeline maintenance and repair. In this way, it ensures a pipeline operating in a safe state. ADPM can be customized not only by data source used for every kind of analysis and assessment but also by the result of the analysis and assessment.

PIM WebGIS is software open to all pipeline operators with the function of spatial location, attribute query, distance measure and online data import which can publish all kinds of pipeline data and provide all the desired results of analysis and assessment. Figure 7 shows queried result of a Lanchengyu pipeline-casing attribute.

[inline:PetrochinaFig7.png=Queried results of Lenchengyu pipeline casing attribute from PIM WebGIS.]

Figure 7: Queried results of Lenchengyu pipeline casing attribute from PIM WebGIS.

Acknowledgments

The authors acknowledge the support of the pipeline integrity research institute of PetroChina Pipeline R&D Center, especially Feng-Qingshan.

Authors

Yi Li is an engineer in the PetroChina Pipeline R&D Center. He is in charge of the pipeline integrity database including model maintenance, data collection and software development.

Haichong Yu is a GIS engineer with a master’s degree and has experience in pipeline integrity database in the PetroChina Pipeline R&D Center.

Lijian Zhou is a senior engineer for PetroChina Pipeline Co. with experience in GIS software development and database management.

Xianjun Tan is an engineer with PetroChina Pipeline Co. with expertise in complex integrity management work and risk assessment.

Comments